Showroom

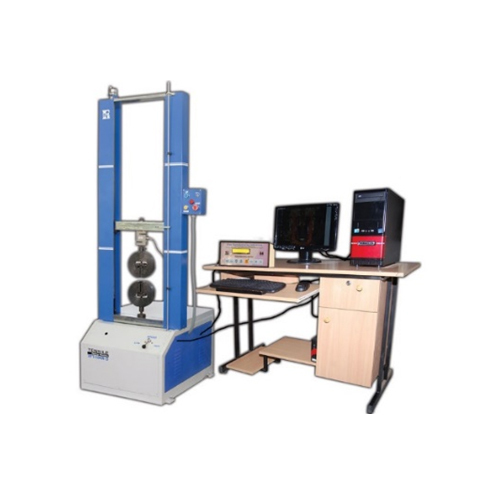

Universal Testing Machines are required in assessing the mechanical behavior of the materials regarding tension, compression, and bending effects. The machines are common in scientific studies and quality assurance, offering accurate outcomes in different industries. They are versatile and robust, and therefore they become a choice in complete material testing.

Tensile Testing Machines are industrial units built to determine the tensile strength and elongation of any material in a precise way. They are very important to the material development, quality assurance, and research laboratories. These are the machines that aid in ensuring that the end products are of required standards, since they can give detailed information on how a particular material performs during the stretch or pull.

Hardness Testing Machines find the resistance of material to deformation or indentation. These machines are used in metalworking, automotive, and aerospace industries to support several testing techniques such as Rockwell, Vickers, or Brinell. The fact that they are efficient and precise makes them important tools for measuring the durability of materials and the quality of manufacturing.

Impact Testing Machines are used to determine the toughness of a material by measuring how much energy a given material can absorb at the time of sudden impact. Applications of the machines include metallurgy, construction, and product testing labs, where they are pivotal in the comprehension of failure behavior. Their precision and stability aid in achieving the safety and reliability in the determination of the material performance.

Compression Testing Machines are used to test the compressive nature of substances such as concrete, metals, and plastic. They are widely applicable in the construction industry as well as testing laboratories in industries to ascertain the ability of materials to resist applied loads without deforming. Such machines are stable, simple to use, and deliver the necessary information for structural stability and creating a product.

Disc Polishing Machines are devices used to prepare metallographic or metal samples so that they may be examined under a microscope. They guarantee non-scratched or distorted surfaces on specimens when their polishing is smooth and homogenous. The machines prove crucial to the research labs, raising precision during micro-structure analysis and quality control stages.

LED Projectors are energy-saving visual devices with bright images that can be used in learning gatherings, corporate, and entertainment presentations. They are long-lasting, have sharp image definition, and high performance with low maintenance. Due to their size and portability, they are perfect for use in dynamic presentation, training, and immersive viewing.

Metallurgical microscopes are special optical techniques used in viewing the microstructure of metals and alloys. Because of their popularity in industrial and research applications, there are very detailed scans that are available on grain structure, defects, and phases. Such microscopes play a very important role in quality control, failure analysis, and developing materials.

Notch Broaching Machines are robust machines that give a notch to test specimens that are to be impacted. The machines are used to reproduce uniform and standard notch dimensions, which are important for getting correct test results of any machine. They find extensive application in mechanical testing laboratories to help provide credible data during the testing of material toughness and research functions.

Universal Strength Machines are high-performance industrial units that are applied in the mechanical testing of different materials such as sand, cement, and metal. They are multi-purpose and sufficiently sturdy, thus would be suitable for foundry applications, construction, and lab use in learning institutions. These machines can give accurate readings on compression, tension, and shear forces used in various applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS